Installation principles

Cushioning layers, i.e. anti-vibration mountings, are generally used in practice for two main reasons.

Practical considerations

Vibration-reducing machine mountings provide constant flexibility in terms of the arrangement of machinery.

Conventional floor anchoring systems are virtually no longer required, and the machines can be adapted to new manufacturing processes with a few simple adjustments. Moreover, the problem of uneven floors can be easily solved with the leveller which is usually integrated.

Safety considerations

Anti-vibration machine mountings are an efficient way of protecting people, the environment, building fabric and the machines themselves. They significantly reduce vibrations and shocks and greatly improve working conditions.

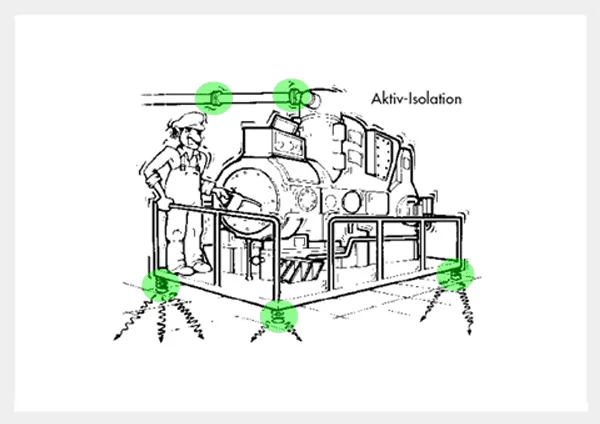

Active or direct isolation means cushioning the jerks and jolts of a working machine,

i.e. to prevent vibrations from impacting on the base, adjoining rooms, buildings, etc. Due account must always be taken of the interference frequency, the structure of the machine and its location. It is the most common method of absorbing vibrations and is used in practically every business or household.

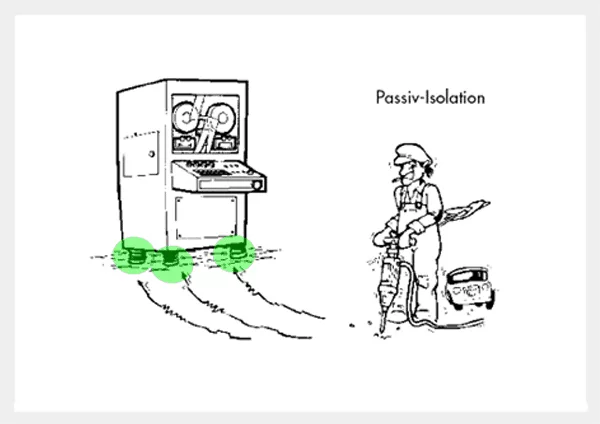

Passive or indirect isolation means shielding sensitive pieces of equipment like weighing machines, measuring instruments and laboratory equipment from jerks and jolts. In this case the vibration control parameters can vary greatly depending on the surroundings, with interference often coming from external sources, such as roads, railways or large construction sites. Given the potential breadth of requirements, it is sometimes advisable to consult a vibration control engineer.

Further information

Rubber as a construction material

Rubber has special properties to offer in comparison with other construction materials. The elongation in some cases can be more than 1,000% and for the most part in the elastic range. Metals, by contrast, have very low strain values below the limit of elasticity.

Design aspects

The load can be increased somewhat in the case of hard rubber. The connection of rubber with metal is not a weak point and stronger than the rubber itself.

Spring material

In the past, cork was usually used as a springy material, the springiness of which was due to compression and relaxation of the trapped air. The spring materials that are coming to the fore today are steel and rubber.