made simple

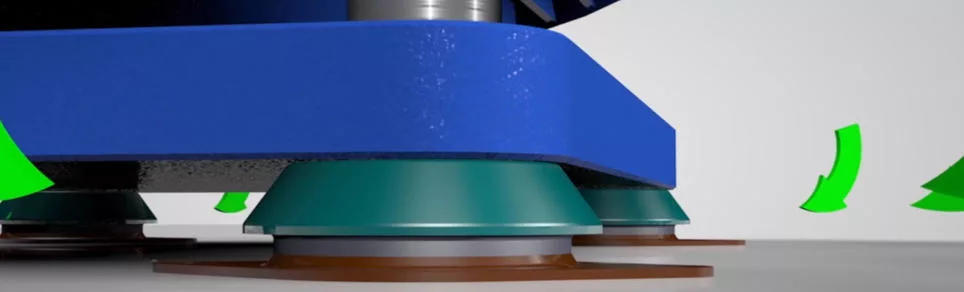

Eliminate machine vibrations with vibration control technology

Many machines cause problems due to disturbing noises and vibrations. The cause lies in their moving and rotating parts – they create an imbalance that leads to annoying vibrations.

Vibration technology supports you in eliminating the unpleasant consequences of vibrations.

FAQ - Questions and answers about vibrations

Many machines cause problems due to disturbing noises and vibrations. The cause lies in their moving and rotating parts – they create an imbalance that leads to annoying vibrations.

Vibration technology supports you in eliminating the unpleasant consequences of vibrations.

Vibration damping efficiently protects people, the environment, building fabric and machinery from noise and damage. They reduce vibrations and significantly improve the working environment.

Many machines generate vibrations through the rotating or oscillating motion of their unbalanced mass. If the machine is rigidly connected to the base, these vibrations will continue to propagate. This is often made clear by disturbing noise, which can be heard not only in the engine room but also in rooms far away. It is usually referred to as structure-borne sound.

In addition to noise, vibrations can cause serious disturbances, especially to sensitive machinery and instruments placed nearby. The human body can also be adversely affected. Especially machines with high speeds generate noise, which can be the cause of reduced working ability, fatigue and headaches.

Today, steel and rubber have prevailed over cork and felt as spring materials. Steel springs usually come in the form of flat coil springs and leaf springs. They offer the advantage of relatively high permissible loads, but provide only extremely small damping. In contrast to steel, rubber has a high level of internal damping. It absorbs sound and has good elastic formability and chemical resistance. These properties make rubber a particularly functional cushioning material.

The geometry of the vibration damper has a decisive influence on the damping result. Two products made from the same material often have completely different properties. Even seemingly identical looking products differ significantly in their performance. Don’t be fooled by supposedly identical, cheaper products. At STS Schwingungstechnik, we test each vibration damper individually and can determine its properties optimally. Our experts will be happy to show you which products are suitable for your requirements. This prevents unnecessary and costly wrong purchases.

Vibrations generated by a plant, machine or vehicle itself. Vibrations and shocks of a working machine are damped by active or direct insulation. In this way, you prevent vibrations from being transmitted to the foundation, adjoining rooms, buildings, etc. Due account must always be taken of the interference frequency, the structure of the machine and its location.

Vibrations that can affect sensitive equipment such as servers, scales, measuring instruments and laboratory equipment from outside and cause malfunctions. They are caused, for example, by road traffic, railways or large construction sites. Passive or indirect isolation can be used to shield such vibrations.

The use of vibration dampers allows flexible installation of your machinery. You can then almost completely dispense with conventional ground anchors. If necessary, the machines can be adapted to the new production processes in just a few steps. In addition, the usually integrated levelling option makes it easy to compensate for any unevenness in the floor.

Further information

Cushioning materials

Cork used to be as favoured as an anti-vibration material due to the springiness caused by the compression and expansion of the trapped air. The cushioning materials which are the preferred choice today are steel and rubber.

Rubber as a construction material

Rubber has special properties to offer in comparison with other construction materials. The elongation in some cases can be more than 1,000% and for the most part in the elastic range. Metals, by contrast, have very low strain values below the limit of elasticity.

Design aspects

The load can be increased somewhat in the case of hard rubber. The connection of rubber with metal is not a weak point and stronger than the rubber itself.

Installation principles

In principle, elastic intermediate layers, i.e. vibration dampers, are installed in practice for two different reasons: Practical considerations and protective considerations.